P whole set

|

|

|

|

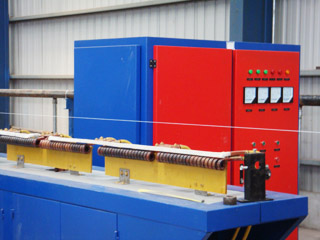

opration desk

|

Wire draw machine

|

|

|

|

|

power supply

|

load&coil

|

|

|

|

|

mechanical transmission

|

control panel

|

|

|

|

|

operation desk

|

cut machine

|

|

|

|

|

straightener machine

|

dragger

|

|

|

|

|

layout of the Line1

|

layout of the Line2

|

|

|

|

|

layout of the Line

|

connect of main induction machine

|

The process of the production process

Pay-off - Tidy line - Straightening - Quench heating- Heat preservation - Cold spray quenching -Tempering heating- Tempering heat preservation - Tempering cooling - Drawing -Oil - Cut - Guide.

Technical description

PC steel bar and spring wire production line by four solid-state static variable frequency heating power supply, four sets of induction heating load capacitance ark, induction heating, heat preservation equipment mechanical drive, ac motor frequency conversion controller, temperature measurement system and centralized control unit, etc.

A. The heating power supply

Production line usually consists of four heating power supply is respectively: KGPS350 kw / 4 ~ 6 KHZ (quenching pre-heating), IPS200kw/30 KHZ (quenching temperature), KGPS160 kw / 4 ~ 6 KHZ (tempering heating), KGPS 100 kw/4 ~ 6 KHZ,insulation (drawing). Specific power selection can be desighed as required.

B. The load coil& capacitor cabinet

Mainly by heating inductor load coil ark, matching electric capacitor, water-cooling copper board, water dispenser, low water pressure protection parts. The cabinet adopts water copper pipe winding, built-in high temperature resistant porcelain tube (porcelain tube belong to wearing parts, shall be the responsibility of the user). Quenching and tempering coils end is equipped with positioning guide, to ensure the operation of steel bar is more stable.

C. Mechanical systems

The whole production line adopts the attachment way, centralized and unified coordination control by PLC, the central console.

D. Drive and control

Because of the PC/spring wire production line for continuous uninterrupted operation, so the automatic control of motor and the power supply is especially important, and will directly affect the quality of the products, motor drive part adopts SIEMENS or ABB inverter power to control the speed of transmission line. By using control by SIEMENS PLC and man-machine interface control system, which can realize the following functions:

1)Production line starts, can automatically complete the drive mechanism and the start of each power supply, and automatically achieve reasonable matching speed and power up. Automatically adjust the heating power, in order to minimize the quenching and tempering temperature fluctuations.

2)Control system has 20 sets of process parameters setting, storage and regulation, modify, statistics, etc.

3)System with functions of closed loop, such as temperature, current, voltage, ensure the production line running according to the optimal process parameters, ensure the quality of products is not influenced by artificial and environmental factors.

4)Take-up adopts horizontal way without tension.

5)Chinese/English graphical text of man-machine interface (touch screen) can be set and real-time display the following parameters:

a. the power supply voltage, power

b. Linear velocity, length, diameter, weight

c. Power supply working condition

d. The fault information display, 10 groups of historical fault storage

e. Working status information display production line

|